Our processes

Step by step

1

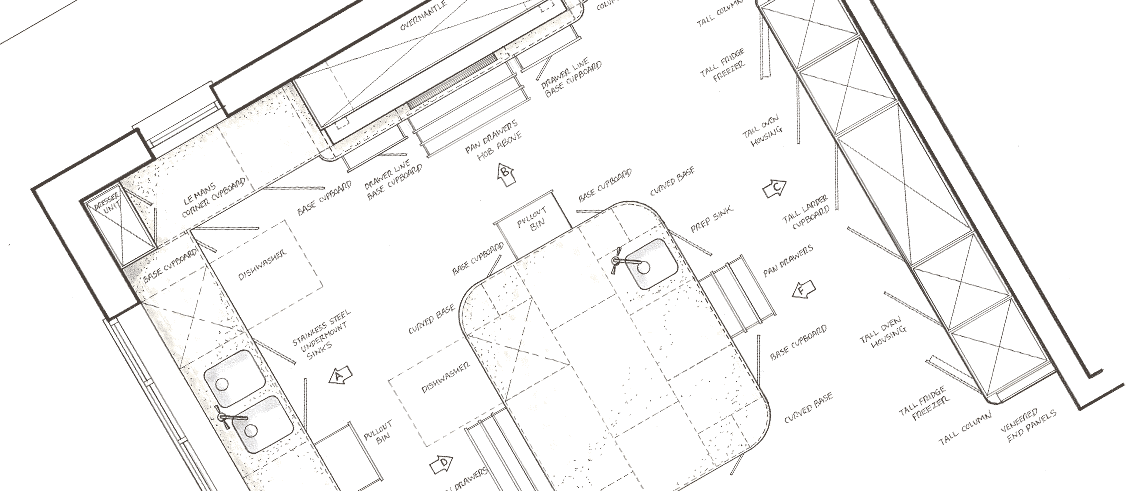

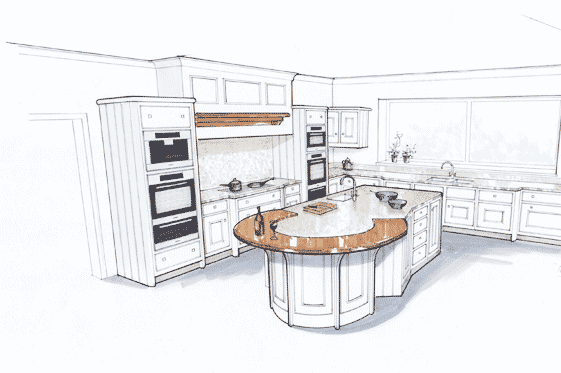

Design &

Project management

Handcrafted furniture starts with handcrafted design. Fordbrook's years of experience and manufacturing capability bring concepts to life. We work from hand-drawings, sketches and the latest CAD programmes, enabling designers to deliver on time and to the highest quality.

“An obsession with detail brings designs to life and makes the impossible, possible”

2

Wood

selection

Too many producers take wood for granted. They fail to appreciate its natural qualities, signature differences and the almost endless possibilities. Fine furniture starts with Fine materials. That’s why we select only the very best, sustainable woods from across Europe and North America.

“The woods we reject are the very materials many furniture manufactures start with”

3

Cutting

& Shaping

Having started with the finest materials Fordbrook treats them with the respect they deserve. Our craftsmen take time to plan grain patterns and complementary colourings, ensuring our furniture is admired for a lifetime.

“From the very first cut, passion and attention to detail prevail in the entire Fordbrook process”

4 Cabinetry

We construct our cabinetry by hand using a combination of traditional methods and high-tech processes. All are complemented with the highest quality fittings and the finest finishes. Years of experience and a constant willingness to be challenged have led to the Fordbrook way of getting it right.

“It’s the little things that count. Our attention to detail is born from an obsessive approach to getting it right”

5 Specials

From complex curves and conical-shaped pedestals to intricate panelling and vast solid-wood worktops. Very few can deal with the scale and complexity of our everyday projects. Our craftsmen use their extensive experience and passion to ensure they get the most from their materials.

“With techniques and customers driving us forward, we have willingly strayed into wood engineering”

6 Assembly

The engine room of the factory. This is where elements of the finished product are brought together, assembled and ruthlessly tested for accuracy and quality. What many think of as tiny details, Fordbrook treats with the utmost importance. These are the details that set us apart.

7 Finishing

At Fordbrook we deconstruct all our cabinetry to ensure accurate finishing and superior results. We continue to work with leading chemists and paint manufacturers, developing outstanding surface paints, lacquers and techniques.

“Fine furniture deserves fine finishing. Our techniques bring quality cabinetry to life”

8

Dispatch &

Delivery

Once reassembled, our furniture is assessed and checked again. Final additions are made and each item is carefully wrapped and packaged, allowing the wood to breath in transit. Alongside our own delivery service, we work with a range of leading partners for destinations across the globe.

“Each item is painstakingly checked and loaded with the care you would expect from Fordbrook”

9 Installation

Our handfinished furniture requires expertise and skill to install. We work closely with leading installation teams to make this process as seamless as possible.

“We work closely with leading installation teams to make the process seamless; focusing on the quality of the end-product throughout”